Double Girder EOT Crane Manufacturers in India - DMH Cranes

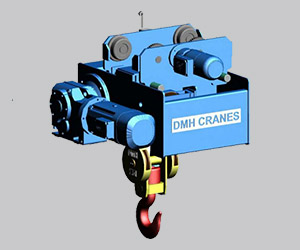

DMH Cranes is a leading Double Girder EOT Crane manufacturers in India, suppliers and exporters in India, are offering new technological double girder EOT crane in India. Our a double girder EOT crane is a type of lifting equipment featuring two parallel bridge beams (girders) supported by end trucks, designed for heavier loads, longer spans, and higher lifting heights than single-girder cranes.

These relate to multiple components such as two girders, top-running or under-running and able to handle heavy types of loads. Due to its smooth working mechanism, these are used in multiple types of applications and industrial sectors. Let’s check out its types, new features and using benefits one by one.

Types of Double Girder EOT Crane:

As former Double Girder EOT Crane manufacturers in India, we are providing the best and new technological automatic Double Girder EOT Crane such as:

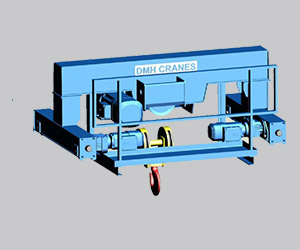

- Top Running Double Girder EOT Crane: We produce Top Running Double Girder EOT Cranes that run over the runway beams in an attempt to obtain the highest amount of lifting capacity and stability. They are utilized where heavy use is expected in terms of bearing capacity. They run longer distances over large work areas so are ideal for production houses and warehouses as well as assembly lines.

- Under Running Double Girder EOT Crane: Our Under Running Double Girder EOT Cranes are precisely engineered to move under the runway beams, hence making them perfect for low-headroom buildings. They provide utmost space utilization with increased lifting capacity. They are designed to be compact so that they can operate in tight areas efficiently without loss of strength.

- Box Girder Double Girder EOT Crane: We manufacture Box Girder Double Girder EOT Cranes that have heavy-duty box-type girders which are highly durable and structurally strong. The cranes resist maximum load without showing minimum deflection and vibration to ensure easy lifting operations. Their increased rigidity renders them most suitable for hard-core applications like heavy engineering shipbuilding and steel processing.

- Motorised Double Girder EOT Crane: As Double Girder EOT Crane suppliers in India, Our Double Girder Motorised EOT Cranes are equipped with the latest motorised drives for hassle-free and smooth operation. Our cranes are so designed that they can minimize labor work and provide more speed and accuracy in lifting heavy loads. With computerised control systems, they provide comparable performance and added productivity in various industrial applications.

- Grabbing Double Girder EOT Crane: We offer Grabbing Double Girder EOT Cranes that are specifically intended to assist in the handling of bulk materials. Equipped with state-of-the-art grab attachments for the lifting of loose products like sand coal and scrap metal efficiently and safely, these cranes possess high speed with a strong grip mechanism and thus serve as a required solution for business firms that process an enormous quantity of raw material.

- Double Girder Magnet EOT Crane: Our Double Girder Magnet EOT Cranes are employed for lifting and transferring ferrous materials with the assistance of heavy-duty magnetic equipment. They are employed on a very large scale in steel mill scrapyards and mills where metal sheet and bar handling are a frequent requirement. Their high magnetic strength facilitates easy lifting and setting and reduces the risk of damage and the risk of safety hazards.

- Steel Plant Double Girder EOT Crane: We manufacture Steel Plant Double Girder EOT Cranes to suit the demanding needs of steel processing and steel manufacturing industries. The cranes are designed to lift incredibly heavy loads like molten metal coils and structural steel members. They possess high heat resistance and sturdy construction that allows them to perform effectively under hot working conditions, thus making them inevitable in steel plants.

Technical Specifications of Double Girder EOT Crane:

As Double Girder EOT Crane suppliers in India, our cranes are equipped with advanced specifications, for additional information, we have mentioned below a technical sheet such as:

| Specification | Details |

|---|---|

| Lift Height | Can lift loads to heights ranging from 6 meters to 30 meters |

| Travel Speed | Moves along the runway at speeds ranging from 10 meters per minute to 40 meters per minute |

| Lifting Capacity | Up to 200 tons or more |

| Span | Typically spans from 10 meters to over 35 meters |

| Hoisting Speed | Lifts loads at speeds from 4 meters per minute to 12 meters per minute |

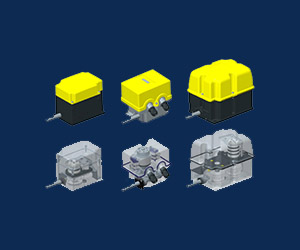

| Control Method | Operated via pendant controls or in a cabin with joystick controls |

| Duty Class | Available in various duty classes (e.g. Class A, Class B, Class C) depending on operational needs |

| Power Supply | 380V to 440V, 50/60Hz, 3-phase |

| Safety Features | Overload protection, emergency stop, limit switches, and anti-collision system |

| Application Areas | Suitable for heavy industries, construction, shipbuilding, steel manufacturing, and warehouses |

| Customization | Can be tailored with different spans, lifting heights, and operational modes |

| Material | Constructed from high-strength steel for durability and long-term reliability |

Top Features Offered by Double Girder EOT Crane Manufacturers in India:

Being the best Double Girder EOT Crane exporters in India, our all types of Double Girder EOT Crane are highly used in multiple types of industries due to its various new features such as:

- Smart Control Systems – We have integrated IoT and remote monitoring into our cranes to enable real-time monitoring and improved diagnostics. These systems offer predictive maintenance that reduces downtime to the barest minimum and improves performance efficiency. Outfitting businesses with analytical capabilities, we enable them to keep their cranes at maximum utilization and avoid breakdowns.

- Variable Frequency Drives (VFDs) – Our cranes are equipped with VFD technology, which eliminates jerky braking and acceleration and accurate load control. Apart from its safety function, it also minimizes wear and tear on the equipment by extending its life. Our state-of-the-art motor management systems offset with varying levels of load with the outcome of making operations energy efficient and more dependable.

- Anti-Sway Technology – We use sophisticated motion control algorithms to reduce load swing to manage high-precision material. The technology maximizes productivity by reducing load stabilizing time to provide faster and more consistent operation. Our cranes contribute to workplace safety through less swinging and smoother movement of materials.

- Auto-Braking System – We have developed an instinctive auto-braking system in case of emergency to avoid accidents and provide maximum safety. Our system releases controlled brake power to avoid jerks, which are dangerous for the load or the crane. Our braking systems are scientifically tested under extreme conditions to ensure stability in every industry condition.

Note: We also provide high-quality and highly efficient Double Girder Goliath Cranes for smooth and safe heavy-duty operations.

Benefits of Using Our Double Girder EOT Crane in India:

Being Double Girder EOT Crane suppliers in India, our all types of cranes give multiple types of benefits such as:

- Greater Efficiency – We mechanize our crane system to keep any type of interference from humans at bay so business can progress at a faster speed and efficiency. Cutting down on downtime and adding throughput through precise computerized load control, we make the workflow smooth and trouble-free of our workers.

- Energy Efficient Operation – We utilize high-performance smart motors and regenerative braking technologies to obtain maximum energy efficiency in reducing the cost of cutting operations by up to 30%. These technologies provide industries with the capability of going green within their own processes without compromising on power and performance.

- Longer Service Life – Our cranes come with corrosion-resistance components and artificial intelligence-powered predictive maintenance that will extend their service life by years. Our cranes continuously track the existing performance levels and detect degradation patterns, and pre-failure maintenance is scheduled before that.

- Safety Refurbishment – We give very high importance to workplace safety by equipping our cranes with the most advanced collision avoidance technology and overload protection technology. They steer clear of potential risk for safe and efficient operation at all times.

Applications of Double Girder EOT Cranes:

As Double Girder EOT Crane suppliers in India, our cranes are highly demanded in multiple types of large industrial sectors and gives higher performance such as:

- Industrial Plants –We offer cranes that deliver smooth and efficient material handling in industrial plants, with easy shifting and lifting of heavy machinery and raw materials. Our precision computerized handling cuts operating delays and optimizes workflow efficiency.

- Steel and Metal Industry – We manufacture cranes that can bear temperature fluctuations and possess enough strength to lift heavy loads appropriate for harsh conditions in steel and metal processing. Our heat-resistant material guarantees perfect performance even under harsh conditions.

- Power Plants – We have remote control systems for our cranes to provide safe heavy machine transfer in complex areas in power plants. Our accuracy technology enables safe and smooth lifting operations without risk and operational inefficiency.

- Shipbuilding Yards – We deploy multi-direction movement technology within our cranes to hoist massive ship components with precision. This guarantees precision in constructing colossal structures in less time and resources.

Being Double Girder EOT Crane manufacturers in India, suppliers and exporters in India, we at DMH Cranes offer versatile and efficient lifting solutions designed for heavy-duty material handling in industrial environments. Featuring a double single-girder structure and optimized design they ensure superior load control stability and durability for smooth and uninterrupted operations even in demanding conditions.

These cranes are built with high-quality materials advanced engineering and precision manufacturing to withstand harsh working environments and heavy operational cycles. Their lightweight yet strong construction reduces structural stress on buildings while ensuring high performance and longevity. For more information, contact us today.